The K 100 walnut cracking machine is an installation for high-quality processing of walnuts on an industrial scale. Thanks to the conical cracking principle, the walnut cracker provides gentle cracking with maximum whole kernel yield and is suitable for processing walnuts of any size.

This nutcracker model is ideal for use in medium and large enterprises, for which the output of the whole kernel is important, and not only the speed of work.

Advantages of K 100 nutcracker:

- It has the best type of cracking - conical.

- Saving time - can work without prior calibration of the walnut.

- High yield of the whole kernel - up to 80%.

- Ease of management - 1 person can handle it.

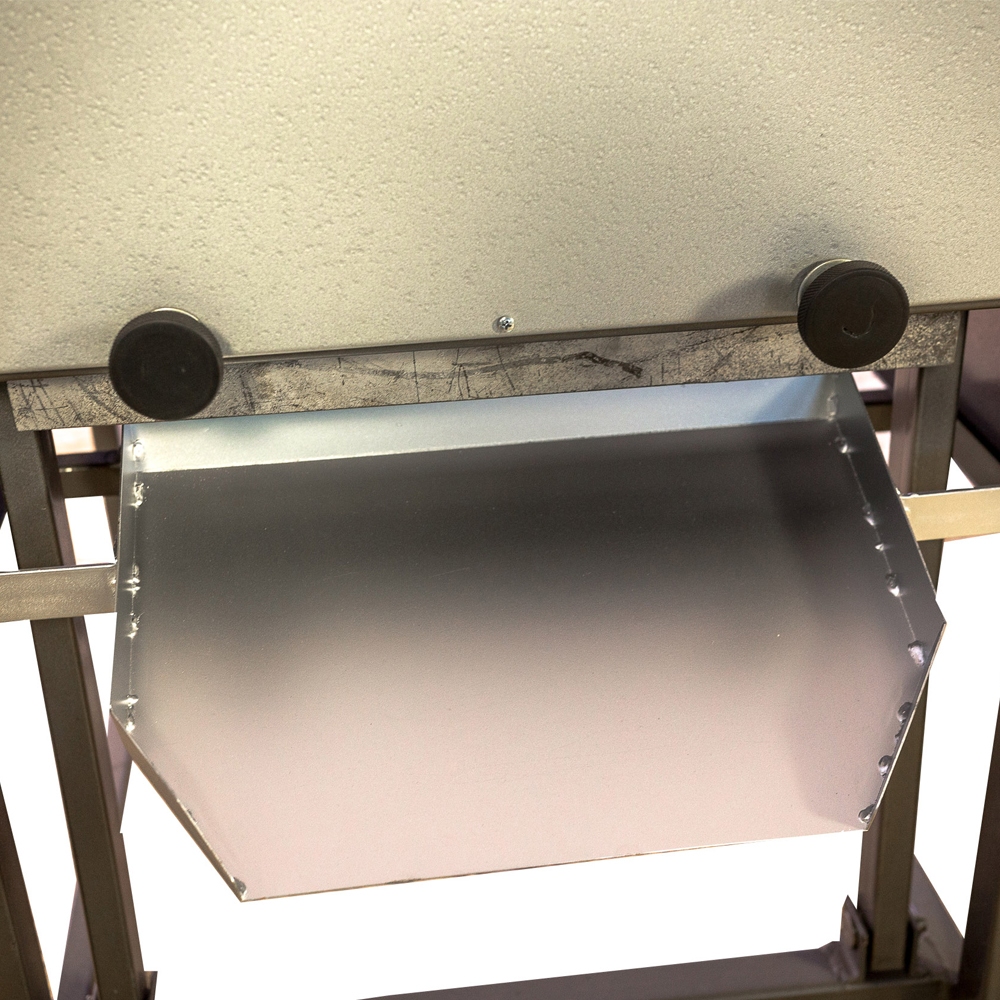

- It has an adjustment of the gap between the piercing plates, which allows you to adjust the nutcracker to the desired walnut caliber right during operation.

- High productivity - capable of processing up to 100 kg of walnuts per hour.

The principle of operation of the nutcracker: the walnut is poured into the hopper and the nutcracker starts. With the help of a vibrating feed, the walnut is fed into the cracking mechanism. The conical slabs shrink and the walnut shells crack, but the kernel remains intact. After cracking, the walnut is sent to the unloading compartment for further bulkhead.

After cracking, the kernel of the walnut can be cleaned from the shell and partitions with walnut cracking kit.

* The color or shade of the product in the photograph may differ from the real one.

Shipping cost is NOT included in the price of the item. To find out the cost of delivery to your country, contact the manager. All about the terms of delivery and payment here.

! Declared characteristics may differ when using low-quality raw materials.

* Low-quality raw materials mean:

- walnut affected by disease, mold or rot;

- a nut with a thick shell and partitions that have grown into the core;

- overdried nut (the kernel crumbles during processing);

- wet elastic walnut, which, after splitting, retains its integrity and will not do without manual cleaning.