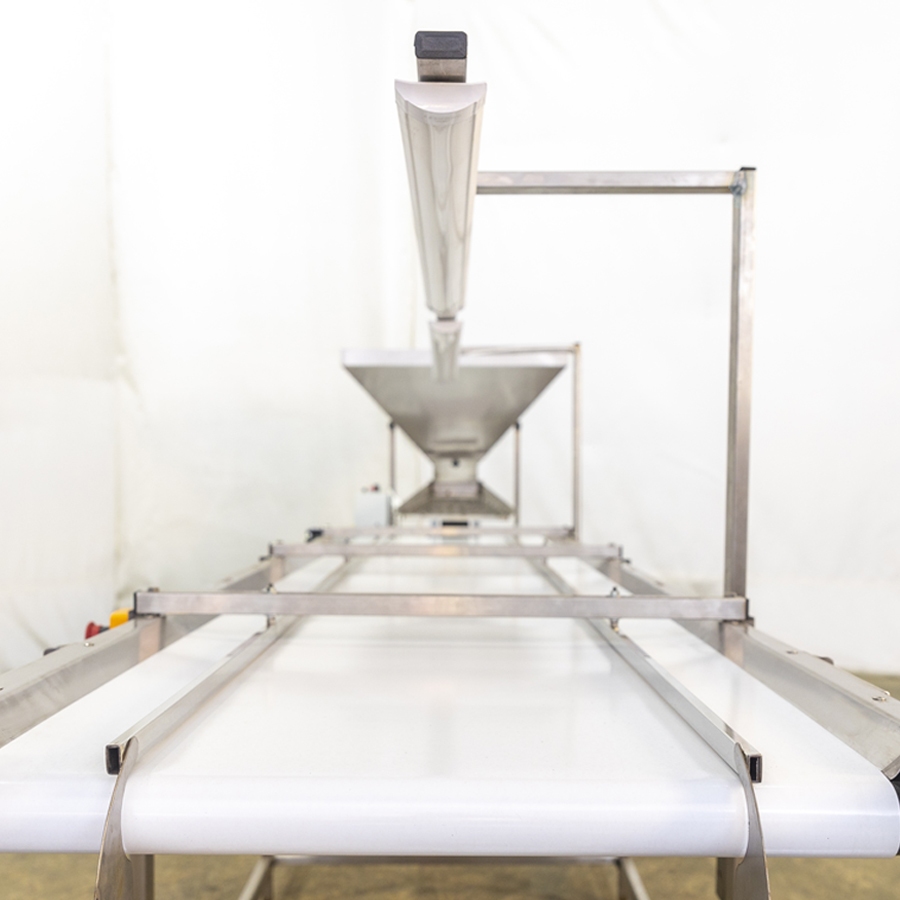

The inspection table is designed for sorting walnut kernels from shells, debris and small particles. The table is capable of providing work from 8 recyclers, depending on the customer's requirements.

The inspection table is used in industrial walnut processing with large volumes of raw materials. The equipment is suitable for the bulkhead of cracked walnuts after the nutcracker and vibrating sieves, for sorting already peeled kernels by color and size, as well as for sorting walnuts in shells.

Advantages of the inspection table:

- Saving time. With the help of the table, personnel will be able to quickly sort the nuts into separate containers without unnecessary movements and operations;

• Convenience of work. The table is equipped with lamps and a contrasting white surface, which will help workers to accurately highlight the desired parts against the background of all raw materials;

• The versatility of the mechanism. The conveyor belt will allow you to sort walnuts and other bulk products according to the necessary criteria;

• The presence of a frequency converter will allow you to control the speed of the belt, depending on the complexity of operations and the number of people;

• Used one of the world's best conveyor belts - Chiorino;

• Possibility to make according to individual sizes.

The principle of operation of the inspection table: pour the walnut into the bunker, with the help of vibratory feeding the walnut is fed to the conveyor belt, where the workers separate the kernel from the shell or sort the kernel by color and size. The sorted walnuts fall into the unloading containers by separators.

*The color or shade of the product in the photograph may differ from the real one.

Shipping cost is NOT included in the price of the item. To find out the cost of delivery to your country, contact the manager. All about the terms of delivery and payment here.