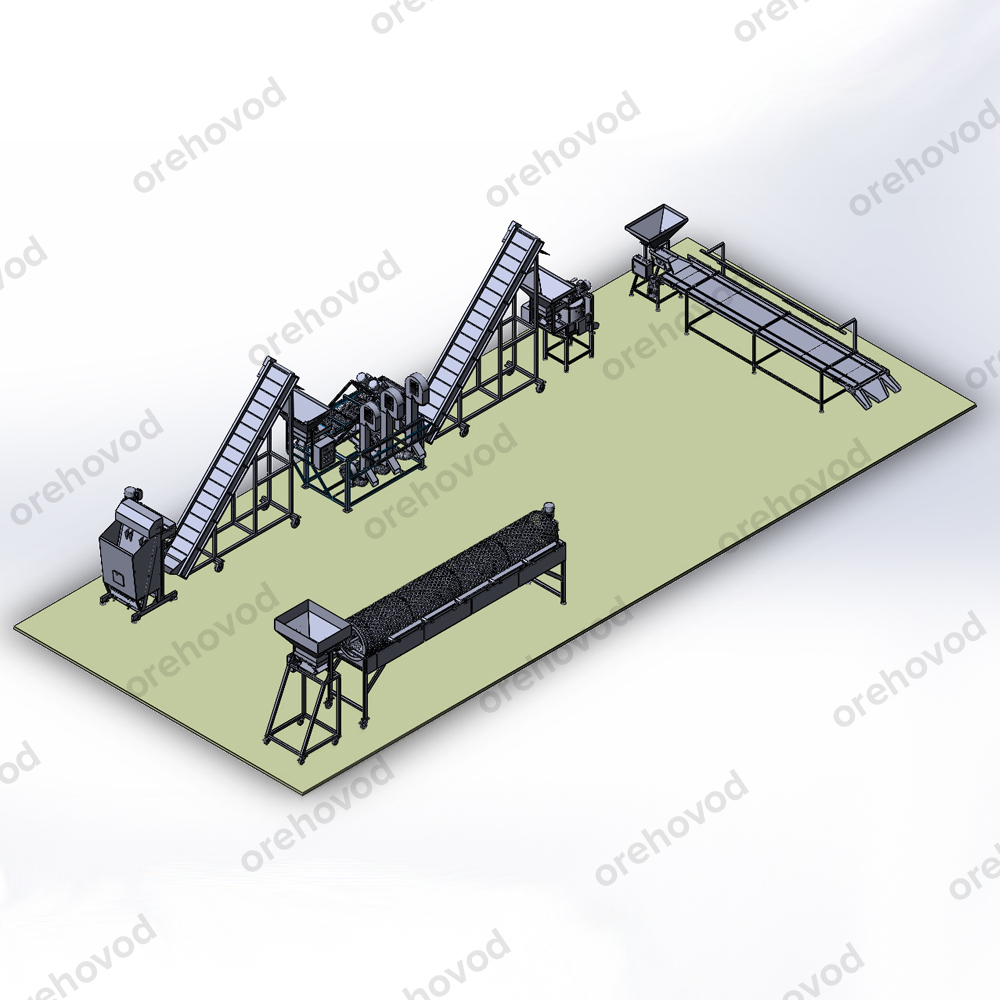

A full range of equipment for walnut processing automates the process as much as possible and minimizes the use of manual force. The line includes all stages of nut processing from sizing of inshell walnuts to visual quality control of the finished kernel. If necessary, the line can be completed with equipment for the collection and washing of walnuts.

The calibrator is designed for sorting inshell walnuts by size. Sizing saves time and effort in setting up the nutcracker and increases the yield of the whole kernel.

| Performance | up to 500 kg/h |

| Number of factions | 8 |

| Hole sizes | on request from 24 to 48 mm |

| Engine power | 0.75 kW |

| Complete set | 220/380 V |

| Warranty | 12 months, post-warranty service |

| Ability to calibrate | walnut |

The automated full-cycle walnut processing line includes the following components:

- Walnut cracking machine Etalon with integrated aspiration column is a walnut cracker of the highest productivity. Due to the conical compression type, the nutcracker can work without preliminary calibration of the walnut and gives a high yield of the whole kernel. Immediately after the nutcracker, the cracked nut enters the aspiration column where the kernel is pre-separated from the shell.

| Performance | up to 200 kg/h |

| Whole kernel output | up to 80% (% may increase or decrease, depending on the quality of the nut) |

| Engine power | 1.5 kW |

| Complete set | 380/380 V |

| Warranty | 12 months, post-warranty service |

| The crack principle | conical |

- Vibrating sieve with aspiration is designed for screening out shells, partitions and dust from the nut kernel and sorting the kernel into fractions (sizes) - halves, quarters, eighths of the kernel and crumbs. Vibrating sieve with aspiration is used for high-quality and quick sorting of nuts in large volumes.

| Performance | up to 300 kg/h |

| Hole sizes | 11, 16, 20/45 mm (can be changed at the request of the customer) |

| Engine power | 3.3 kW |

| Complete set | 220/380 V |

| Warranty | 12 months |

- The lifting conveyor is used to move the walnut between installations, namely from the nutcracker to the walnut breaker (re-cracker). The conveyor reduces manual labor and keeps equipment running smoothly.

| Hopper height adjustment | there is |

| Engine power | 0.55 kW |

| Complete set | 220 V |

| Warranty | 12 months |

In the processing of walnuts from the population there will be a percentage of undershoot, since the majority of walnuts are not varietal. For quick processing, reducing the amount of manual labor and automating production, a walnut breaker is used.

- The walnut breaker is installed immediately after the nutcracker, before sorting on the vibrating screen.

| Performance | up to 200 kg/h |

| Kernel output | Crumb, 1/8 and ¼ (depending on nut quality and settings) |

| Engine power | 1,1 kW |

| Complete set | 380 V |

| Warranty | 12 months, post-warranty service |

| The crack principle | drum |

The inspection table is used to visually inspect the walnut kernel. The kernel moves along the belt and the staff monitors the quality, in case of finding an unsuitable kernel or pieces of shell, it is removed to the side.

| Speed regulation | there is |

| Belt speed | 0.1-0.3 m / s |

| Engine power | 0.55 kW |

| Complete set | 220/380 V |

| Warranty | 12 months |

Approximate calculations and costs of equipment productivity, rental of premises:

Industrial line capacity up to 200 kg/h. With a standardized 8-hour working day, the equipment is capable of processing up to 1600 kg of walnuts (calibration, splitting, sorting of nuts).

One operator is required to service each unit. The optimal number of personnel for continuous and high-quality operation of the equipment: 8-13 people (the number will depend on the premises, the experience of the workers, the number of undershoots).

- Premises: from 100 sq.m.

- Line length: 1580 cm.

- Line width: 590 cm.

- Approximate electricity costs: 58,4 kW:(0,75+1,5+3,4+0,55+0,55+0,55)*8 = 58,4 kW.

* Where 8 is the number of hours, and in brackets is the power consumption of each unit.

- Number of staff: 8-13 people.

* The line can be converted and completed according to the requests and requirements of the client.

* The color or shade of the product in the photograph may differ from the real one.

Shipping cost is NOT included in the price of the item. To find out the cost of delivery to your country, contact the manager. All about the terms of delivery and payment here.

! Declared characteristics may differ when using low-quality raw materials.

* Low-quality raw materials mean:

- walnut affected by disease, mold or rot;

- a walnut with a thick shell and partitions ingrown into the kernel;

- overdried walnut (the kernel crumbles during processing);

- wet elastic walnut, which, after splitting, retains its integrity and will not do without manual cleaning.