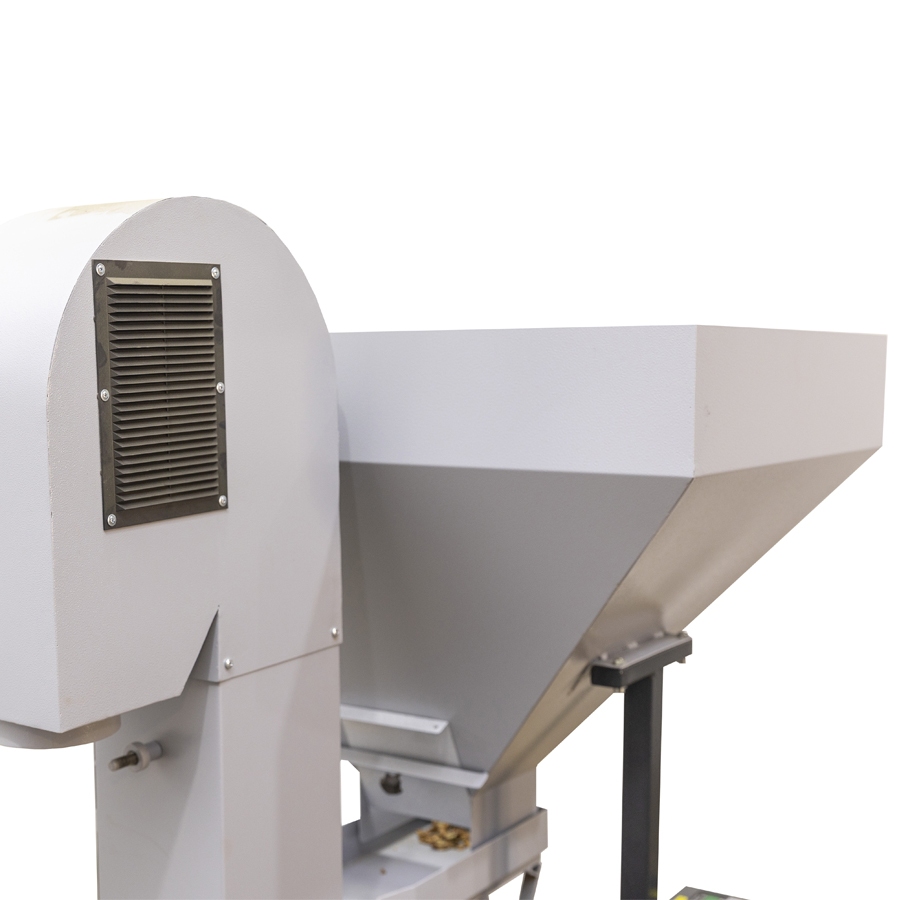

The aspiration column is an installation for separating the shell, partitions, dust and debris from the walnut kernel. It speeds up the processing of walnuts and increases the quality of the kernel at the output - the kernel is clean, without debris, dust and pieces of shell. The vibrating feed frees from the constant manual feeding of the nut, so that the worker can service other installations while the aspiration column is in operation.

Advantages of an aspiration column:

- The equipment separates the kernel from the shell as efficiently and quickly as possible.

• Autonomy - 80% replaces manual labor (depending on the quality of the walnut).

• Versatility - Easy to adjust for other crops thanks to variable air flow.

• Ease of use - even one person can handle the column.

• Vibration feeding completely frees you from manually placing the nut in the column.

The principle of operation of the column: a cracked nwalut is poured into the bunker and starts up, the vibratory feeding feeds the walnut into the column, the shell and other debris are separated and sifted out from the nut kernel by a powerful air flow. The kernel is transferred to a container for further sorting by size, and shells, debris and small chips through a pipe to another container.

*The color or shade of the product in the photograph may differ from the real one.

Shipping cost is NOT included in the price of the item. To find out the cost of delivery to your country, contact the manager. All about the terms of delivery and payment here.

! Declared characteristics may differ when using low-quality raw materials.

* Low-quality raw materials mean:

- walnut affected by disease, mold or rot;

- a walnut with a thick shell and partitions that have grown into the kernel;

- overdried walnut (the kernel crumbles during processing);

- wet elastic walnut, which, after splitting, retains its integrity and will not do without manual cleaning.